Supply Chain Analytics: Data-Driven Decision Making

admin

- 0

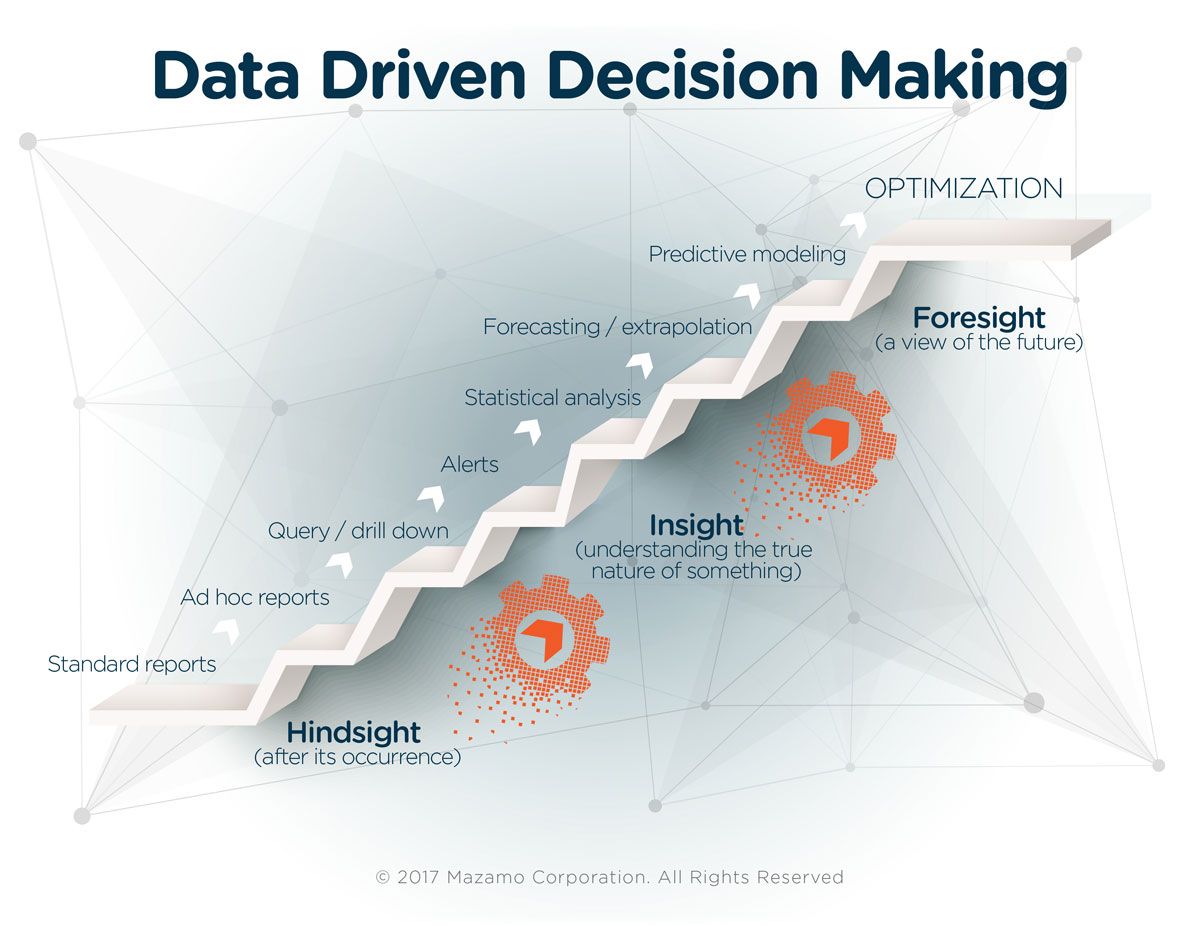

In today’s competitive and fast-paced business environment, companies across various industries are leveraging data-driven decision making to optimize their supply chain operations. Supply chain analytics is the practice of collecting, analyzing, and interpreting vast amounts of data to gain valuable insights that drive better decision making throughout the supply chain. In this article, we will explore the importance of supply chain analytics and how it enables organizations to make informed choices that enhance efficiency, reduce costs, and improve customer satisfaction.

The Power of Data in Supply Chain Management

Effective supply chain management requires a deep understanding of various factors such as demand forecasting, inventory management, production planning, and logistics optimization. Gathering and analyzing relevant data allows organizations to uncover trends, patterns, and correlations that are crucial for making informed decisions in these areas. With the advent of advanced technologies and the rise of the Internet of Things (IoT), supply chains generate an enormous amount of data every day. This data includes information from sensors, RFID tags, GPS tracking devices, customer feedback, and other sources. Supply chain analytics enables companies to harness this data and transform it into actionable insights, thereby facilitating data-driven decision making.

Benefits of Supply Chain Analytics

Implementing robust supply chain analytics practices provides numerous benefits to organizations. Let’s explore some of them:

Improved Forecasting Accuracy

Accurate demand forecasting is essential for optimizing inventory levels, production planning, and procurement. By analyzing historical sales data, customer sentiment, market trends, and external factors, supply chain analytics allows organizations to enhance forecasting accuracy. This leads to better inventory management, reduced stockouts, and improved customer satisfaction.

Enhanced Operational Efficiency

Supply chain analytics helps identify bottlenecks, inefficiencies, and areas for improvement within the supply chain. By analyzing data related to production processes, transportation routes, and warehouse operations, organizations can optimize their operations and reduce costs. This leads to shorter lead times, increased throughput, and improved overall efficiency.

Optimized Inventory Management

One of the biggest challenges for supply chain managers is striking the right balance between inventory levels and customer demand. Supply chain analytics allows organizations to analyze historical demand patterns, variability, and seasonality to optimize inventory management. By implementing data-driven inventory strategies such as just-in-time (JIT) or vendor-managed inventory (VMI), organizations can reduce carrying costs, minimize stockouts, and improve cash flow.

Effective Supplier Management

Data-driven decision making enables organizations to evaluate and manage their supplier relationships more effectively. By analyzing supplier performance data, delivery times, quality metrics, and other relevant factors, organizations can make informed decisions when selecting and managing suppliers. This leads to improved supplier collaboration, reduced risks, and better overall supply chain performance.

Improved Customer Satisfaction

Supply chain analytics allows organizations to analyze customer data, including purchase history, preferences, and feedback. By leveraging this information, organizations can personalize their offerings, improve service levels, and enhance customer satisfaction. By meeting customer expectations and delivering products on time, organizations can gain a competitive edge in the market.

Implementing Supply Chain Analytics

Adopting an effective supply chain analytics strategy requires the integration of technology, processes, and skilled professionals. Organizations need to invest in advanced analytics tools, data management systems, and cloud-based platforms to handle the vast amount of data. They also need to have skilled data scientists, analysts, and supply chain professionals who can derive valuable insights from the data. Additionally, organizations need to establish a data-driven culture, where decision making is guided by insights derived from analytics. This involves training employees on data literacy, promoting cross-functional collaboration, and aligning objectives with the organization’s analytics goals.

Conclusion

In an increasingly complex and competitive business environment, supply chain analytics has become essential for organizations to thrive. By leveraging data-driven decision making, organizations can optimize their supply chain operations, reduce costs, enhance efficiency, and improve customer satisfaction. It is crucial for businesses to invest in the right infrastructure, talent, and processes to fully harness the power of supply chain analytics and stay ahead in the market.